Edges

Bearing Edges - Spaun Double 45 Degree

The most critical part of the drum sound is determined by the bearing edge. Many drum companies rely on expensive machinery that lacks the perception of the human eye. At Spaun Drum Company, each bearing edge is cut, checked, double-checked, and re-cut if needed to insure a consistent and flat edge for the drum head to rest on.

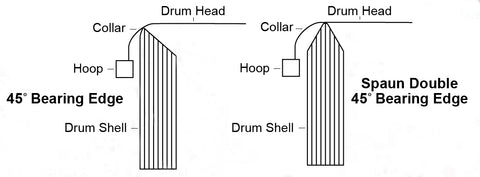

What matters most with the bearing edge is how much wood touches the drum head and where it touches. Many drum companies talk about "X degree angle" on this drum and "Y degree angle" on that drum. The truth is, that makes no difference in the sound of the drum unless it changes... how much wood touches the drum head and where it touches! Most drum companies use a single 45 degree bearing edge with a slight round over or counter-cut, if any at all. It works okay and is easy to program a machine to do the job. Here's the problem: the bearing edge rests on the collar of the drum head instead of the flat surface of the drum head!

Spaun Drums feature a Double 45 degree Bearing Edge which insures proper drum head alignment and puts the bearing edge where it's supposed to be... on the flat surface of the drum head, not the collar! This promotes both easier tuning as well as a broader tuning range. Tired of over-tightening your drum heads just to get proper seating? Now you won't have to!

We know what your thinking... two edges must take twice as much work. You're right! It's critical to the sound of your drum, and absolutely worth the extra effort!

Our Classic Rounded edge reduces the initial attack of the drum and provides a darker, more subtle voice. The tone is more "rounded" and less aggressive. These edges are typical on older, vintage drums. For this reason, we use this edge on our vintage styled drums like the Jazz Custom, Revolutionary, and Vintage Mahogany/Maple Series. You can request this edge on any drum, but our Double 45 Degree Edge is standard on our other Series. If you have a Custom bearing edge request, it's no problem for us to include that on your shells.